Mechanical parts inspection

Bopteq have over 230 sets inspection equipment.Germany zeiss Measuring Machine SKY I CNC, Italian Coordinate Measuring Machine SKY I CNC;Germany LH54 Measuring Machine SKY I CNC, U.S. MICROVU Tooling Measuring Microscope; Italian one-meter Profile Project , TOPCON 2D Measuring Microscope from Japan ;Contracer/Surf-test Mitutoyo Japan SV-C3100S8; Kovoetekt, Czechoslovakia do-o pc gear test instrument ;Precision round-test Mitutoyo Japan.

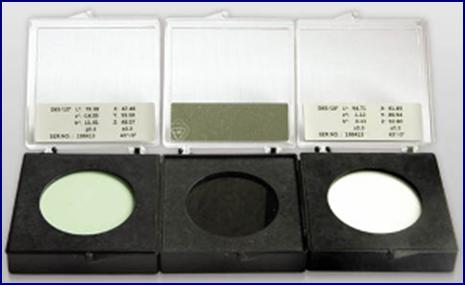

Measurement centering

Optical inspection machine

BopteQ quality assurance system is designed to ensure that every step, from raw materials to final products is under strict quality control . Every step is under take under guided by ISO :9001:2000 procedure . As a major part of Bopteq operation System .

Bible opteQ Quality Control System monitor every respect of the business procedure :from raw materials sourcing , producing , logistic to ensure we would keep provide our customer with stable quality Analytical methods Our products are carefully monitored during all stages of production - from raw material to the finished product.

.jpg)

During the production process, various quality assurance steps are carried out, including Visual inspection Chemical analysis Physical analysis The chemical analysis is carried out in our own QA lab and also through cooperate with external partner ,we would guarantee a high level of quality and consistency by using following method ICP spectroscopy Atom absorption Metallic analysis by GDMS Scanning electron microscopy Physical analysis (particle size distribution, laser diffraction)

Production Qualification Equipment

Perform full qualification tests on all new models and monitoring tests on production units.

- Walk-in Chamber

- Epoxy Decapsulation system

- PCB contamination test machine

- Thermal shock chamber

- Hast chamber

- High temperature high humidity chamber

- Freezer

- ESD tester

- Vibration machine

- Packing Drop Tester

- Press-test machine

- Rub tester : Eraser Test & RCA Tester

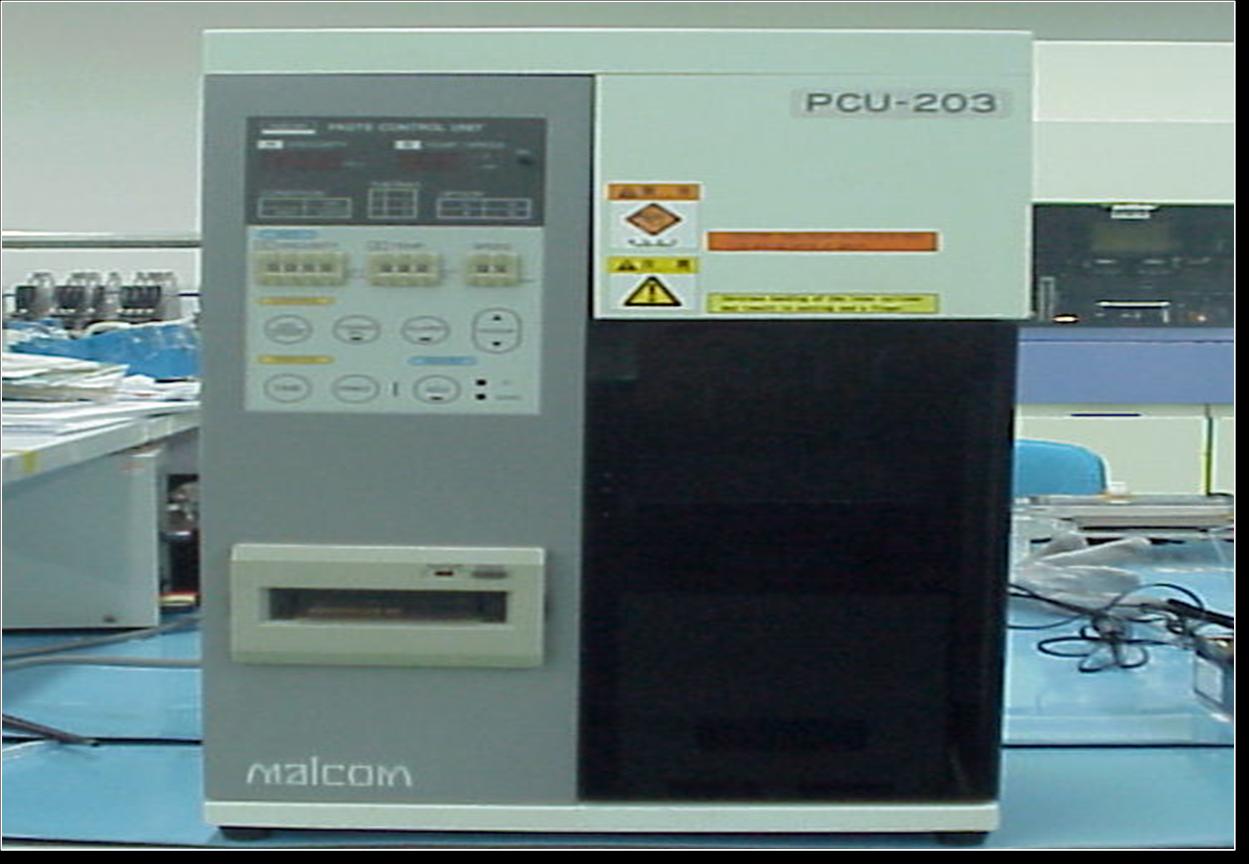

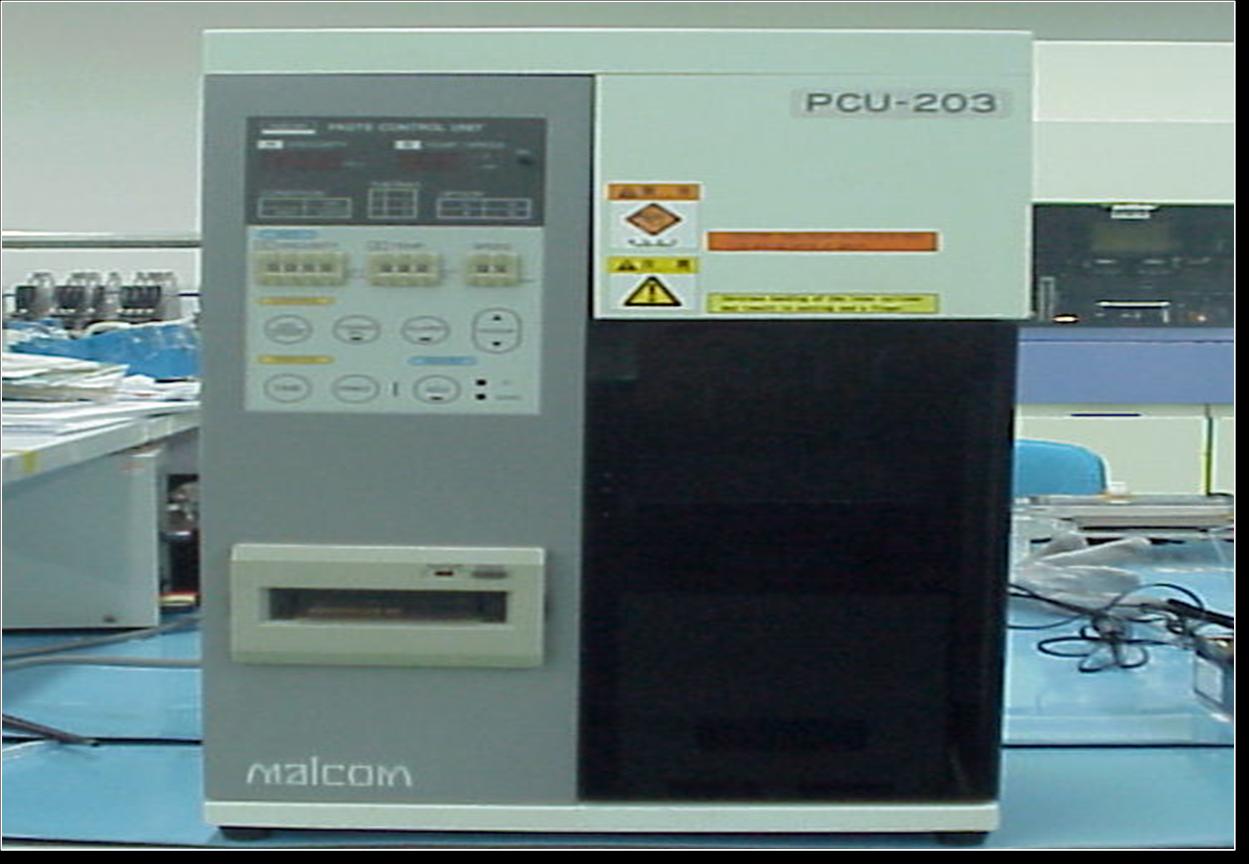

Solder Paste Thickness Checking machine

Measurement range: 5Pa.S~1000Pa.S

Speed range: 1~50RPM

Measurement accuracy: +5% of indicated value

Speed accuracy: +2% of set point

Repeatability: +1.0%

Sensor: Malcolm Spiral Pump Type

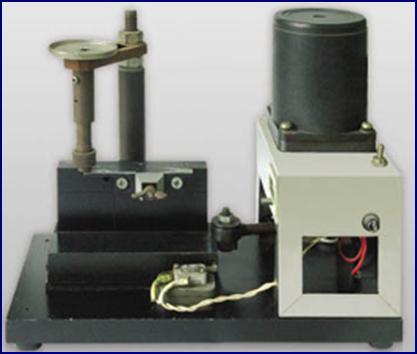

Packing Drop Tester

Load weight: 100kgs

Test height: 30-200cm

Drop mode: corner, edge, side drop test

Hast Chamber

High stress and moisture

absorption conditions to

accelerate component degradation)

Temperature Range: 105°C ~ 162°C

Humidity Range: 75% ~ 100% RH

Pressure Range: 0.2~4.0 KG/Cm3

|

.jpg)

.jpg)

.jpg)